The fusion of 3D printing technologies with the dynamic world of wearable devices promises a future where our clothes, accessories, and even our skin are augmented with sensors, trackers, and energy storage to serve functions far beyond their traditional roles.

This article delves into the convergence of 3D printing in the fabrication of cutting-edge wearables—self-powered and smart—redefining the boundaries of what wearable technology can be.

With the ability to customize and create intricate 3D-printed circuitry, the new era of consumer wearables is set to be as unique as the people who wear them.

Article Outline:

- What Makes 3D Printing Ideal for Creating Wearable Devices?

- How Do 3D Printing Technologies Enhance the Customization of Wearables?

- In What Ways Are Self-Powered Wearable Devices Changing the Game?

- From Concept to Reality: How are Wearable Sensors Created with 3D Printing?

- Can 3D Printing Meet the Needs of Mass Production for Wearables?

- What are the Latest Advancements in 3D Printing Materials for Wearables?

- How Will Future Technologies for Wearables Benefit from 3D Printing?

What Makes 3D Printing Ideal for Creating Wearable Devices?

The intricate nature of wearable devices, often requiring precise, lightweight, and skin-friendly forms, makes 3D printing an ideal manufacturing method.

With its layer-by-layer approach, the 3D printing process can fabricate items that conform to the contours of the human body, creating wearable electronics that are both comfortable and functional.

Additive manufacturing offers a degree of flexibility and complexity in design that traditional manufacturing methods simply cannot achieve, making it perfectly suited for the bespoke nature of wearables.

3D-printed wearables can integrate both functional and structural elements into a single item. Sensors, energy storage components, and soft stretchable materials come together seamlessly, producing items like fitness trackers and smart glasses that are becoming staple fineries in the tech-forward ensemble.

Furthermore, the rapid prototyping capabilities of a 3D printer allow developers to iterate designs quickly and cost-efficiently, accelerating the journey from idea to commercial product.

How Do 3D Printing Technologies Enhance the Customization of Wearables?

One of the standout advantages of 3D printing technologies is its ability to customize. For wearables, this means products can be tailored to fit the ergonomic and aesthetic preferences of individual users.

3D printing can adapt to the unique shapes and sizes of different bodies, ensuring that wearable devices not only fit perfectly but move and flex as the user does, offering an unparalleled level of personalization in the fabrication of wrist-mounted wearable devices and other wear-friendly gear.

New 3D printing methods, such as fused deposition modeling (FDM) and selective laser sintering (SLS), promote design freedom, allowing manufacturers to cope with intricate designs that were previously unattainable.

By using a 3D model as a blueprint, manufacturers can now translate complex geometries into wearable forms with precision, integrating various printing materials to achieve the desired mechanical properties and comfort.

In What Ways are Self-Powered Wearable Devices Changing the Game?

The emergence of self-powered wearable devices is a game-changer in the wearables industry, owing largely to developments in 3D printing technologies.

Freed from the constraints of traditional energy sources, these devices harness motion, body heat, or solar power to function, eliminating the need for batteries and creating an entirely new concept of self-sufficiency in wearable tech.

3D printing has been pivotal in developing this new hybrid form of wearables, enabling engineers to embed energy-harvesting technologies directly into garments and accessories.

The layer-by-layer printing method allows for the integration of piezoelectric sensors or photovoltaic cells into the structure of the wearable, hence ensuring the performance of printed devices while maintaining flexibility and comfort.

From Concept to Reality: How are Wearable Sensors Created with 3D Printing?

The process of turning a wearable concept into a reality has been optimized through 3D printing technology. Sensors that track health metrics or environmental data are crucial to many wearable applications, and additive manufacturing is at the forefront of creating these small, intricate components.

The printing method allows developers to create highly stretchable wearable sensors that conform to the human body, maintaining functionality without sacrificing user comfort.

Advanced 3D printing techniques like multi-jet fusion and SLA have enabled the production of customized, complex shapes and conductive pathways necessary for wearable sensors.

This streamlined printing process is essential for capturing the nuances of the human form and the minute details required for sensor functionality.

Can 3D Printing Meet the Needs of Mass Production for Wearables?

While 3D printing is often associated with prototyping or small-scale fabrication, the technology is evolving to meet the needs of mass production for wearables.

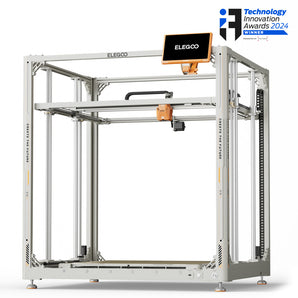

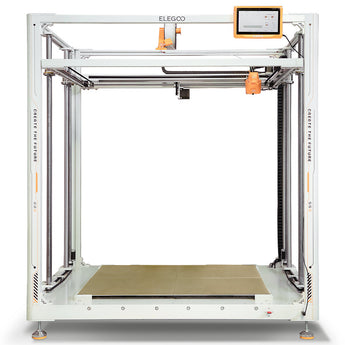

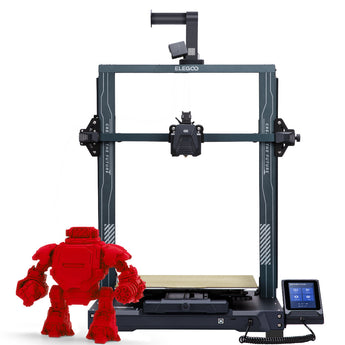

The Neptune 4 Max is our recommended FDM 3D Printer for Wearables.

The advent of high-speed 3D printers and the refinement of manufacturing processes have positioned additive manufacturing as a viable option for large-scale production.

The challenge lies in optimizing the printing speed and materials used to ensure time-efficient and cost-effective production without compromising the quality of the wearable products.

Manufacturing methods are adapting to incorporate 3D printing in assembly lines, where the flexibility of the printing process can be leveraged to produce a wide range of wearable devices.

As printers become faster and more precise, the transition from traditional to 3D-printed wearables in mass quantities becomes increasingly plausible.

What are the Latest Advancements in 3D Printing Materials for Wearables?

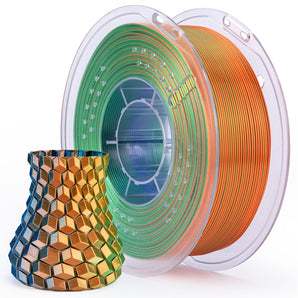

The development of 3D printing materials is vital to the advancement of wearable technology.

As wearables demand materials that are flexible, durable, and sometimes bio-compatible, the 3D printing industry has responded with new formulations that combine strength with flexibility.

Innovations in printing materials, such as conductive inks and silicone-like resins, have enabled the creation of printed circuits that can bend and stretch along with the movements of the human body.

These latest materials are being tested for their stretchable properties and how they interact with skin, aiming to provide maximum comfort while still incorporating the necessary electronic components into wearable devices.

As 3d printing materials evolve, the potential for creating more sophisticated and diverse wearables grows, enabling a broader range of applications in fitness, health monitoring, and beyond.

How Will Future Technologies for Wearables Benefit from 3D Printing?

The trajectory of both wearable technology and 3D printing indicates a future of increased collaboration and innovation.

Emerging technologies for wearables, such as augmented reality interfaces and advanced health monitoring systems, will benefit from the prototyping and production capabilities of 3D printing.

As new use cases for wearables are discovered, 3D printing will continue to be a critical tool in materializing those ideas into tangible, wearable forms.

The capacity to integrate a wide range of functional elements into soft, adaptable fabrics or plastics heralds a new wave of breakthroughs in the design and usability of wearable technology.

From enhanced data-gathering wearables to seamlessly integrated smart fabrics, the convergence of these disciplines promises an exciting future for consumer technology and personal devices.

In summary, here are the core takeaways:

- 3D printing revolutionizes wearable tech design and manufacturing for optimal body fit.

- Customization is a key benefit of 3D-printed wearables, offering tailored fit and design.

- 3D printing is vital in developing self-powered wearables with integrated energy-harvesting.

- Wearable sensors made via 3D printing provide precise, flexible health and environment monitoring.

- Despite challenges, 3D printing is adapting to large-scale wearable tech production.

- Advances in 3D printing materials are crucial for wearable device development and comfort.

- As wearables advance, 3D printing remains essential for prototyping and production.