In the adrenaline-pumped world of FPV (First Person View) drone flying, customization is not just a preference; it's a necessity.

From enhancing aerodynamics to protecting delicate components, the evolution of 3D printing technology has opened up a new frontier for drone enthusiasts.

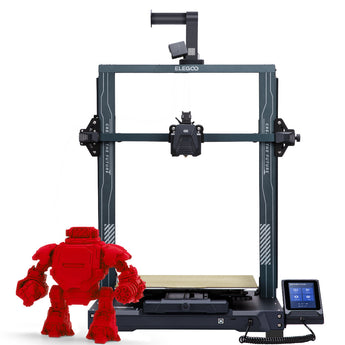

This article dives into how you can leverage an ELEGOO 3D printer to create custom drone parts, specifically focusing on TPU (Thermoplastic Polyurethane) accessories that promise durability and flexibility.

Whether you're a seasoned pilot looking to upgrade your quad or a beginner eager to assemble your first drone from scratch, understanding the synergy between 3D printing and drone customization can significantly boost your FPV experience.

Outline

- Why Choose 3D Printing for Your Drone Parts?

- Key 3D Printed Drone Components You Should Consider

- The Process: From Design to Flight

- Beyond the Basics: Advanced 3D Printing Techniques for FPV Drones

Why Choose 3D Printing for Your Drone Parts?

The customization of drone parts through 3D printing not only allows for a high degree of personalization but also improves the functionality and resilience of your FPV drone.

Advantages of custom 3D printed parts include the ability to rapidly prototype and test various designs, ensuring a perfect fit for specific models or needs. When it comes to selecting materials, TPU stands out for its flexibility and durability, making it ideal for parts that require impact resistance, such as arm guards and antenna mounts.

However, PLA Plant Based Resin can be a viable option for non-flexible components that benefit from rigidity, like frame inserts or lightweight camera mounts.

The choice between these materials ultimately affects your drone's performance and durability, highlighting the importance of material selection in 3D printed projects.

Key 3D Printed Drone Components You Should Consider

For those looking to enhance their FPV drones, there are several key components to consider 3D printing.

Protective gear such as arm guards and lens protectors can significantly reduce damage during crashes or rough landings. Performance parts, including custom frames and antenna mounts, not only allow for a tailored flight experience but also improve the drone's aerodynamics and signal reception.

Additionally, aesthetic accessories like uniquely designed canopies or battery holders can give your drone a personalized look while ensuring functionality is not compromised.

The Process: From Design to Flight

The journey from conceptual design to taking your drone to the skies involves several crucial steps.

Designing your parts can be facilitated by a variety of software programs and online templates, tailored to the specifications of your drone.

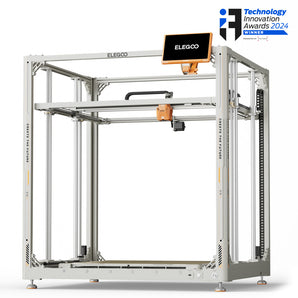

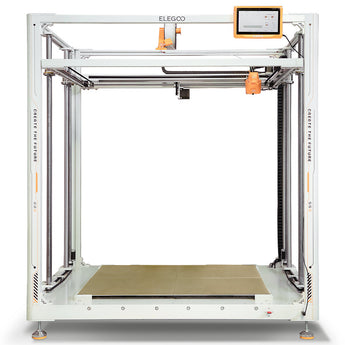

When it comes to 3D printing essentials, choosing the right printer, such as the ELEGOO Neptune 4 Plus, and adjusting settings like infill and layer height, can make a significant difference in the quality and durability of your printed parts.

Post-processing and assembly tips, including proper cleaning, sanding, and the application of adhesives, ensure a secure fit and finish, readying your drone for its maiden flight.

Beyond the Basics: Advanced 3D Printing Techniques for FPV Drones

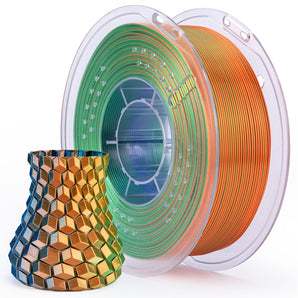

As you delve deeper into the world of FPV drones and 3D printing, exploring advanced techniques can offer further improvements to your drone's performance and appearance. Experimenting with different 3D filaments, such as PETG for its strength and temperature resistance, can open up new possibilities for parts that require specific attributes.

Enhancing print quality through machine calibration, layer optimization, and the use of supports can result in smoother and more reliable components.

Lastly, tapping into the wealth of customization hacks shared within the FPV community can inspire innovative solutions and designs, pushing the boundaries of what's possible with 3D printed drone parts.

Summary

- 3D printing offers unparalleled customization and functionality for FPV drone parts, with materials like TPU providing flexibility and durability.

- Essential components for 3D printing include protective gear, performance parts, and aesthetic accessories, each contributing to the drone's overall performance and style.

- The process from design to flight involves careful planning, selecting the right 3D printer and settings, and meticulous post-processing to ensure parts are flight-ready.

- Exploring advanced 3D printing techniques and materials can further enhance your drone's capabilities, encouraging continuous learning and experimentation within the FPV community.

Embracing 3D printing in the construction and customization of FPV drones not only fosters innovation but also enhances the flying experience.

With the right tools, materials, and a bit of creativity, the possibilities are as boundless as the skies your drone will explore.