We cover a lot of the more popular 3D Printing Projects out there, and this usage is likely one of the more useful from a medical point-of-view.

The world of dentistry is experiencing a revolution with the use of 3D printing technology. From the creation of precise dental models to the manufacturing of customized dentures, 3D printing is setting new standards in dental care and significantly transforming the dental industry. Read on to understand how 3D printing is used in dentistry, its numerous applications, and why this technological evolution is worth considering in every dental practice.

Article Outline

- Introduction to 3D Printing in Dentistry

- How Does a Dental 3D Printer Work?

- What are the Applications of 3D Printing in Dentistry?

- How are Dentures made using 3D Printing?

- How are Dental Aligners created using 3D Printing?

- What is the Role of 3D Printing in Dental Implants?

- How is 3D Printing influencing Digital Dentistry?

- What is the Future of Dental 3D Printing?

- Are there any Limitations to Dental 3D Printing Applications?

- What are the best Dental 3D Printers?

- Conclusion: The Impact of 3D Printing on the Dental Industry

Introduction to 3D Printing in Dentistry

3D printing, also known as additive manufacturing, has found numerous applications in dentistry, opening new avenues for personalized patient care. From printing dental implants to crowns and bridges, the technology is poised to redefine the way dentists practice.

Thanks to 3D printing, dental professionals can now create custom dental appliances and solutions based on a patient’s dental anatomy, offering a significant improvement in comfort and fit compared to traditional methods.

How Does a Dental 3D Printer Work?

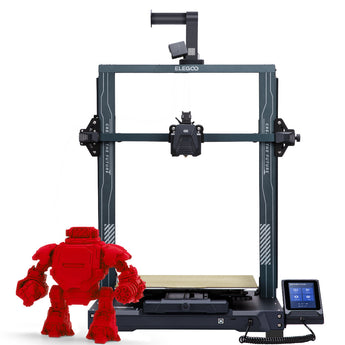

A Resin Printer is most suitable for printing Dental Crowns & Implants, compared to FDM 3D Printers. A resin 3D printer is widely used in dentistry due to its ability to create objects with a high degree of precision and a smooth surface finish. Using 3D printing technologies and multiple materials, these printers can fabricate a variety of dental appliances, including crowns, bridges, and even full dentures. A dental 3D printer works by using digital files derived from the patient's intraoral scanner data to create a 3D print.

What are the Applications of 3D Printing in Dentistry?

There are many dental applications for 3D printing. An example includes the production of dental models for surgical planning, dental aligners, crowns, and bridges.

In fact, one of the earliest uses of 3D printing in dentistry was for the creation of surgical guides for implant placement. 3D printing using biocompatible dental resins enhances the accuracy of dental implant procedures.

How are Dentures made using 3D Printing?

3D-printed dentures represent a significant leap in dentistry. Traditional denture fabrication is a labor-intensive process that requires multiple appointments and manual labor. However, with 3D printing, the process is digital, quicker, and more accurate.

The digital workflow involves creating a 3D scan of the patient's mouth using an intraoral scanner, designing the dentures using dental CAD software, and then using a 3D printer to print the dentures. The result is a more accurate fit, increased comfort for the patient, and reduced manufacturing time.

How are Dental Aligners created using 3D Printing?

The use of 3D printing technology in creating dental aligners has revolutionized orthodontic treatment. Dentists can make patient-specific aligners using a combination of 3D scanning and 3D printing technologies.

After obtaining a 3D scan of a patient's teeth, dentists can modify the digital model to plan the treatment. The series of custom aligners are then 3D printed, which gradually move the teeth to their correct position.

What is the Role of 3D Printing in Dental Implants?

Implant dentistry is another area where 3D printing has made significant strides. Dentists use 3D printed surgical guides during the implant placement procedure to ensure accurate positioning of the implant.

This direct 3D printing approach reduces the possibility of error during the surgical process and enhances the overall success rate of dental implants.

How is 3D Printing influencing Digital Dentistry?

Digital dentistry is a rapidly growing field that integrates various technologies to improve dental practices' accuracy and efficiency. 3D printing plays a pivotal role in this transformation.

Besides enabling the production of dental restorations and appliances, 3D printing facilitates the creation of patient-specific dental models used for diagnostic purposes and treatment planning.

What is the Future of Dental 3D Printing?

3D printing in dentistry is only set to expand in the future. As technology continues to evolve, it is anticipated that 3D printing will be used to create more complex dental devices and play a role in regenerative dentistry. Moreover, as 3D printers become more affordable and user-friendly, they are likely to become an integral part of every dental practice and laboratory.

Are there any Limitations to Dental 3D Printing Applications?

Despite the many advantages, there are still some limitations to consider. Although 3D printing is rapidly evolving, not all materials used in traditional dental restorations can be printed yet. Additionally, there's a steep learning curve associated with digital workflow and 3D printing techniques that can be challenging for some dental professionals.

What are the best Dental 3D Printers?

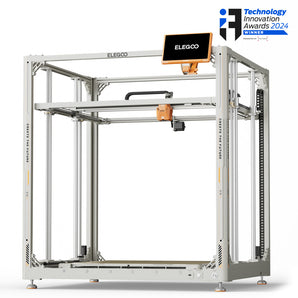

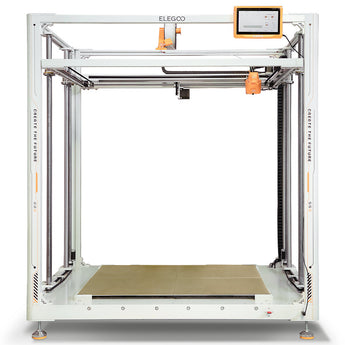

We sell Resin 3D printers, with our latest models being the Saturn 3 Resin 3D Printer and Saturn 3 Ultra Resin 3D Printer.

What Should You Look For?

We identify four criteria that you should consider:

- Print Quality: Dental applications require high-precision and detailed prints. Look for a printer that offers high-resolution printing, typically indicated by a smaller XY resolution (around 50 microns or less) and layer height (below 200 microns).

- Material Compatibility: Ensure the printer is compatible with biocompatible resins suitable for dental use. These resins should meet medical-grade standards for patient safety and can be used to produce dental models, surgical guides, aligners, crowns, bridges, etc.

- Print Speed: Dentistry often requires a quick turnaround. A printer with a fast print speed will allow for more efficient production of dental parts.

- Support and Maintenance: We pride ourselves on our reliable customers, especially when using the printer for medical purposes. Our printers are easy to maintain, and we can provide a 1-Year warranty for support.

The two printers we recommend are:

- Saturn 3 Resin 3D Printer

- Saturn 3 Ultra Resin 3D Printer

Conclusion: The Impact of 3D Printing on the Dental Industry

In conclusion, 3D printing is transforming dentistry, paving the way for innovative dental solutions and superior patient care. By improving the accuracy of dental models, enhancing the fit of restorations, and allowing for patient-specific treatment plans, 3D printing is becoming a game-changer in the dental industry.

Key Takeaways:

- 3D printing is revolutionizing dentistry by enabling the production of personalized dental appliances and solutions.

- Dental 3D printers use digital files derived from intraoral scans and can fabricate a variety of dental appliances with high precision.

- 3D printing finds applications in various aspects of dentistry, from creating surgical guides for implants to manufacturing dentures and aligners.

- 3D printed dentures and aligners offer improved fit and comfort, along with reduced manufacturing time.

- Despite its numerous advantages, 3D printing in dentistry also has some limitations, including material constraints and a steep learning curve associated with digital workflows.

- The future of dental 3D printing is promising, with expected advancements in technology and applications in regenerative dentistry.

Other Cool Ideas & Categories

The realm of 3D printing has expanded beyond mere prototypes, bringing to life, for example, some of the best board game projects and enhancing tabletop gaming experiences. For the enthusiasts amongst you, the attraction doesn't stop there; the options are unlimited, from for example, crafting intricate diorama projects that beautifully capture miniature worlds, and the cosplay community is thriving with uniquely printed accessories and costumes that will stand out at every convention. jewelry designers are also getting creative with this technology, crafting beautful pieces that are as detailed as they are unique.

On a more practical note, 3D printing is revolutionizing household solutions with the DIY home projects and (for example) tailored garden tools. Parents and educators are appreciating the innovation within the 3D toy project space, many of which have strong educational undertones. The medical field, particularly dentistry, is witnessing a transformation as precise tools and molds are printed to cater to individual patient needs. Notably, advancements in 3D braille printing materials are making a significant difference in the visually impaired community, promoting inclusivity. Meanwhile, the sports industry is benefiting too, with custom equipment being designed for optimal performance.