Which material is most commonly used for 3D printing? It is estimated that the first material that pops up in the minds of people familiar with the 3D printing industry is Photopolymer Resin. Photopolymer Resin is a kind of 3D printing material, with smooth surface, high precision, surface can be painted, hardness is not bad. Photopolymer resin is very suitable for printing prototype models, such as design models, but also those with special requirements in terms of functions, such as those with high temperature resistance or higher toughness.

The Photopolymer Resin is molded by SLA/DLP technology. SLA is also called light curing molding. It uses ultraviolet light or other light beams to cure the liquid Photopolymer Resin. Learn More about 3D Printer Technologies FDM vs SLA vs MSLA by

Characteristics of Photopolymer Resin

The Photopolymer Resin is generally in a liquefied state, and the printed objects using this material generally have the characteristics of high strength, high temperature resistance, and water resistance. However, the Photopolymer Resin material is not used for a long time, and it is easy to cause hardening.

Specific Characteristics of Photopolymer Resin:

1. Low viscosity;

2. Small curing shrinkage;

3. Fast curing rate;

4. Small swelling;

5. High light sensitivity;

6. High degree of curing;

7. High wet strength.

In addition, the price of Photopolymer materials is more expensive than the desktop-level PLA, and at the same time, since it needs to be poured into a container during use, it is easy to cause waste.

Application of Photopolymer Resin

The finished product of 3D printing of Photopolymer Resin material has good details and high surface quality, which can be colored by painting and other processes. However, if the Photopolymer Resin printed items are exposed to light for a long time, they will gradually become brittle and yellow. This material is mostly used to print fine models and complex design models that require high model accuracy and surface quality, such as prototypes, hands, jewelry or precision accessories, etc. But it is not suitable for printing large models. If you need to print large models, you need to disassemble and print them.

In addition to the high toughness, high-temperature resistance, and ordinary Photopolymer Resins mentioned above, there are translucent and fully transparent Photopolymer Resins. However, it should be reminded that both translucent and fully transparent printing require post-grinding and special surface treatment. If there is no treatment, the transparency will be slightly worse.

The Photopolymer Resin material not only has a good molding effect, but is also relatively cheap, so it has become the material of choice for printing prototypes. For whether it is feasible to make a sample for appearance and function verification before the product goes on the market, this proofing fee is really very cost-effective. Compared with direct production without proofing, a large part of the money can be saved.

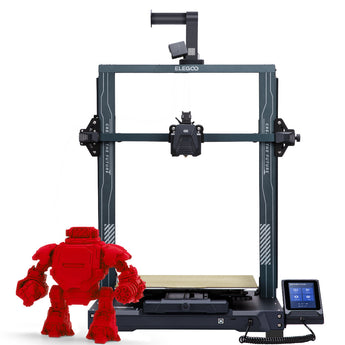

ELEGOO Photopolymer Resins

1. Standard Photopolymer Resin 【MSDS Sheets】

| Printing Setting: (For Mars) | Resin Parameters: |

|

|

2. ABS-Like Photopolymer Resin 【MSDS Sheets】

| Printing Setting: (For Mars) | Resin Parameters: |

|

|

3. Water Washable Photopolymer Resin 【ROHS, REACH & MSDS Sheets】

| Printing Setting: (For Mars) | Resin Parameters: |

|

|

4. Plant-Based Photopolymer Resin 【MSDS Sheets】

| Printing Setting: (For Mars) | Resin Parameters: |

|

|

Precautions: (Dealing with resin could be messy and risky sometimes. To have a safer and better user experience, please follow the instructions below:)

-

Shake well before use

-

Recommended best printing temperature 25°C-30°C

-

Always wear gloves and mask to avoid direct skin contact

-

Keep away from children, dust and direct sunlight

-

Wash with plenty of water immediately if you get direct skin contact with resin

How to Setting Resins on ELEGOO Printers?

-

Unofficial suggestions for most brands resin on ELEGOO Mars Seires Printers (Contributed by our community members)

-

Unofficial suggestions for most brands resin on ELEGOO Saturn Seires Printers (Contributed by our community members)

How to store SLA/DLP/LCD UV curable resin?

-

Do not overfill the resin container, you need to reserve a small amount of space.

-

Do not pour used, uncured resin back into new resin bottles.

-

For long-term storage, please pour the resin into an opaque container separate from the resin tank, avoid direct sunlight and within the temperature range recommended by the manufacturer.

-

Do not store uncured resin in refrigerators used for food and beverage storage.

- Do not use resin printing models for storing food or long-term contact with human skin.

Tips and Tricks: Things You May Not Know About SLA/DLP/LCD Resin (by Chitubox.com)